What is a Grease Trap?

A grease trap (also known as a grease interceptor) is a plumbing device designed to trap or intercept grease and food waste before it enters a waste water disposal system and public sewers.

What are my Options?

There are two types of grease traps – electric and passive.

- Electric grease traps use a heating element to skim surface FOG (fats, oils & grease) into a removable receptacle. They are typically situated indoors, under sinks and require daily cleaning and maintenance.

- FOG in a passive grease trap rises to the surface while waste food sinks to the bottom. Only greywater exits the trap. Passive traps can be made to measure and are installed outdoors, indoors, above ground or below ground. They require no maintenance or intervention from staff.

Why do I need a Grease Trap?

There are two reasons why all Food Service Establishments need a grease trap.

- It prevents liquid FOG (fats, oils & grease) from entering your plumbing system.

- It is a legal requirement to restrict your FOG from entering the public sewer.

What Should I Consider Before Buying?

- Will my grease trap pass an Irish Water inspection?

- Is it 100% sealed to prevent malodours & leaks?

- Will my staff have to maintain and clean it?

- What is the manufacturer’s life expectancy?

- What are the maintenance and running costs?

It pays to do some research. Ask other food operators to share their experiences and ask your supplier to provide as many references/testimonials as possible. Then, take the time to speak with some of them. See More.

“Investing in an off-the-shelf grease trap may prove costly and disruptive as we can insist on it being replaced. It pays to do a little research beforehand.”

– Irish Water Inspector

“Investing in an off-the-shelf grease trap may prove costly and disruptive as we can insist on it being replaced. It pays to do a little research beforehand.”

– Irish Water Inspector

Why is Correct Sizing Important?

An undersized grease trap will not separate grease correctly as hot water from appliances will simply wash liquified FOG’s through the unit where it will later cool and solidfy in pipes and drains.

Sizing a grease trap correctly requires a skilful assessment of the food service establishment. Critical information such as water temperatures, flow rates, meals served per day etc. play a significant part in determining the volume of the unit.

Investing in a non-compliant or off-the-shelf grease trap can prove costly and disruptive as Irish Water Inspectors can insist on it being replaced. It pays to do a little research beforehand.

Grease traps manufactured outside of Ireland that do not carry the relevant NSAI or CE certification are not permitted.

Do I need to Inform Irish Water Prior to Installing A Grease Trap?

Yes. Irish Water requires food operators to provide sizing and design details when installing or replacing a grease trap. However, we provide this as a free service. Prior to fabrication and installation, we submit an application to Irish Water on your behalf.

We ensure that all your compliance obligations have been satisfied and we will assist you in applying for a Trade Effluent FOG Licence. What is a Trade Effluent FOG Licence?

How Will I Know if my Grease Trap is Sized Correctly?

As a Local Authority approved supplier we will provide a sizing calculation in accordance with I.S. EN 1825 Parts 1 & 2. This is an important document as Irish Water Inspectors will ask to see it during their routine inspections.

An accurate sizing calculation cannot be provided without a detailed survey of the premises.

Free Site Survey

We provide a free nationwide site survey for:

- Food Operators

- Builders / Contractors

- Architects / Engineers

Free Sizing Calculator

Accurate sizing is critical when making a submission to Irish Water. This free sizing calculator can provide approximate sizing based on the FOG (fats, oils & grease) producing equipment that is currently in use.

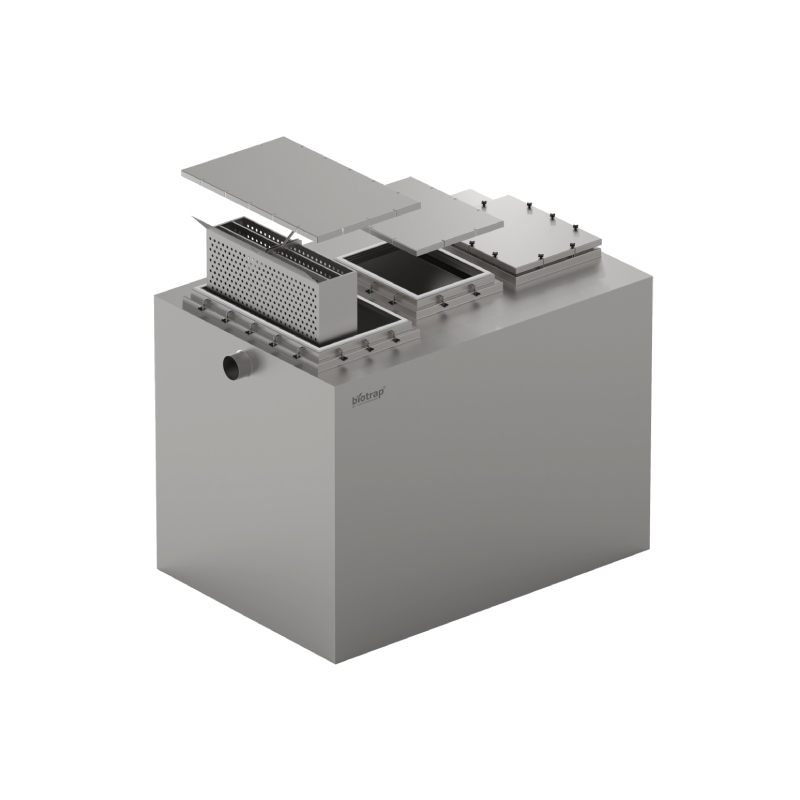

BIOTRAP®

No Blockages. No Bad Odours.

No Blockages. No Bad Odours.

Taylormade For Your Premises.

If you are a busy food operator you’ll know how expensive and disruptive a poorly designed grease trap can be to your business. They can leak, give off bad odours, consume huge amounts of electricity and require frequent cleaning and emptying?

Hundreds of Irish Food Service Establishments have said goodbye to their outdated grease trapping equipment and are enjoying the benefits of a taylormade BIOTRAP®.

Not only are our valued clients compliant with mandatory wastewater regulations they are also reporting zero blockages and bad odours, zero downtime and substantial savings compared to other systems.

We are confident that your food operation will benefit from our time-proven maintenance programme allowing you and your staff to focus on your core business with total peace of mind.

Just Ask Our Customers.

We manufacture, install and maintain passive grease traps for many of Irelands leading food operators. We are happy to provide contact details for any of our clients featured in the testimonial section. See More.

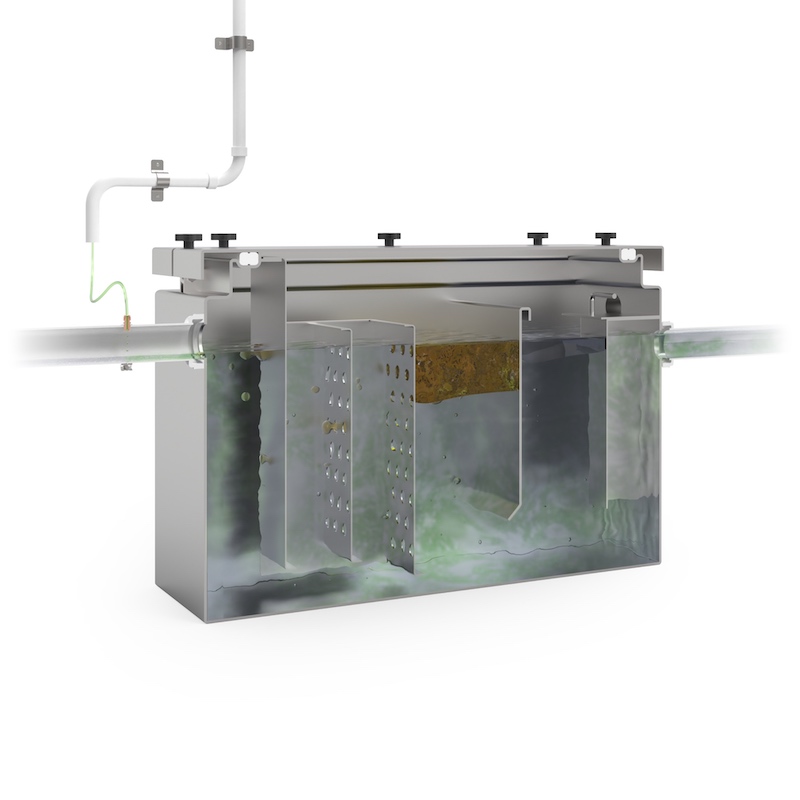

How the BIOTRAP® Works.

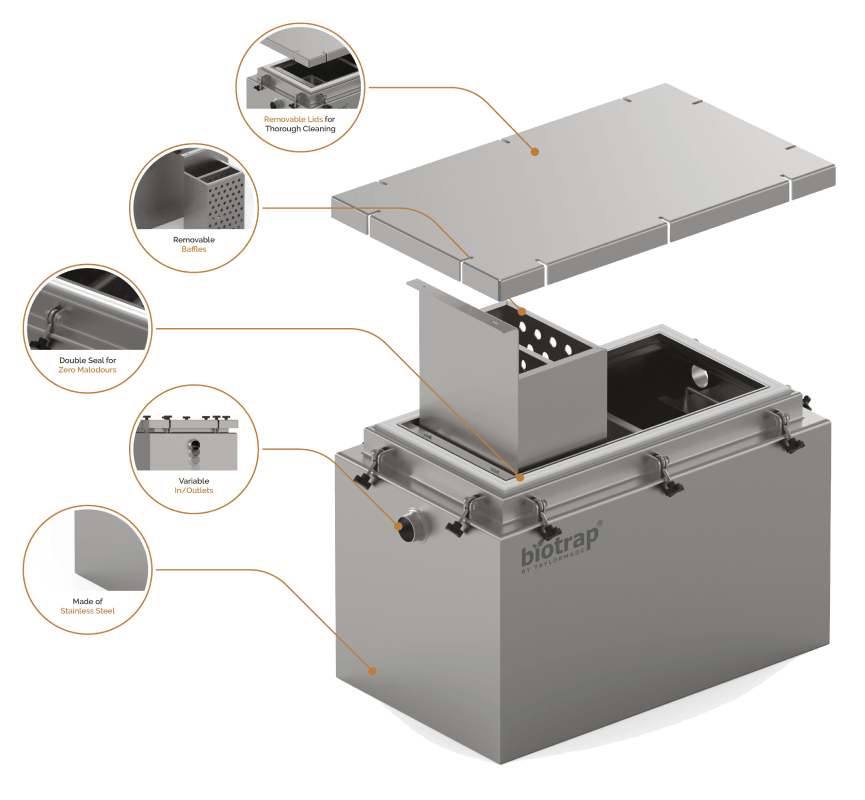

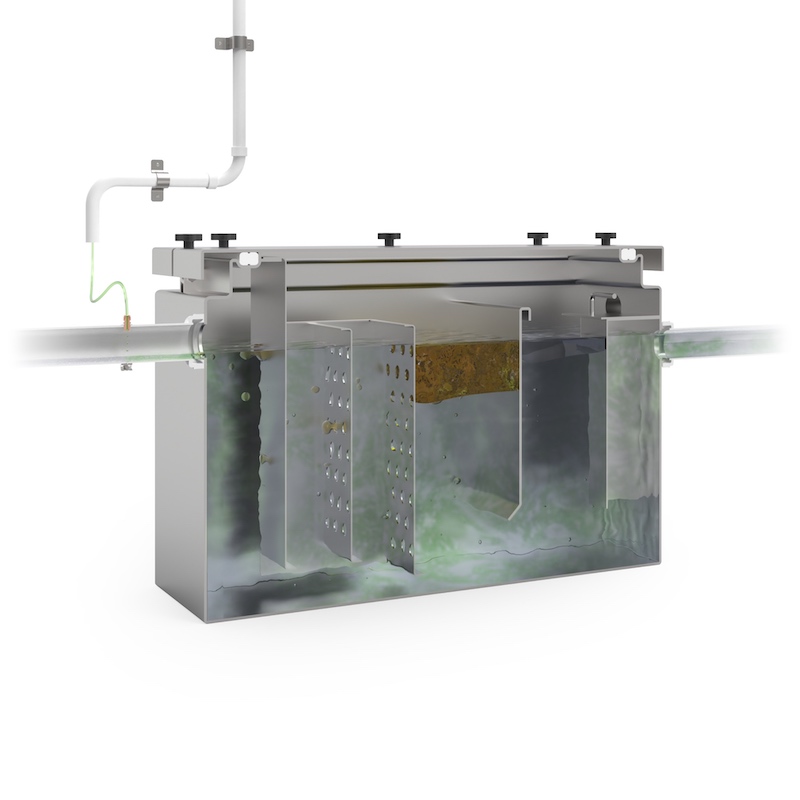

As wastewater enters the BIOTRAP® the internal stainless steel baffles reduce the flow allowing the water to cool quickly. FOG (fats, oils & grease) then rises to the surface while food particles sink to the bottom.

Our Irish Water approved bacterial additive (not enzymatic) is automatically dosed into the unit each evening via a timed dosing pump. The micro-organisms in FAT ATTACK® break down FOG (fats, oils & grease) and digest all solid waste on contact which keeps the BIOTRAP®, as well as drains and pipes free-flowing and functioning like new.

There’s no moving parts, filters, or bags to replace. BIOTRAP® requires no daily maintenance by staff, consumes zero electricity, and can be retrofitted in almost any kitchen (above or below ground). With a 25+ year life expectancy* and a 100% airtight design, BIOTRAP® is the most hygienic and cost-effective interceptor on the market.

The Benefits.

- Zero Staff Maintenance

- Zero Smells or Leaks

- Zero electricity costs

- 25 Year Life Expectancy

- Optional SLA (Service Level Agreement)

- Unlimited Support

The BIOTRAP® Range

Available in Standard & Made-to-Measure Sizes

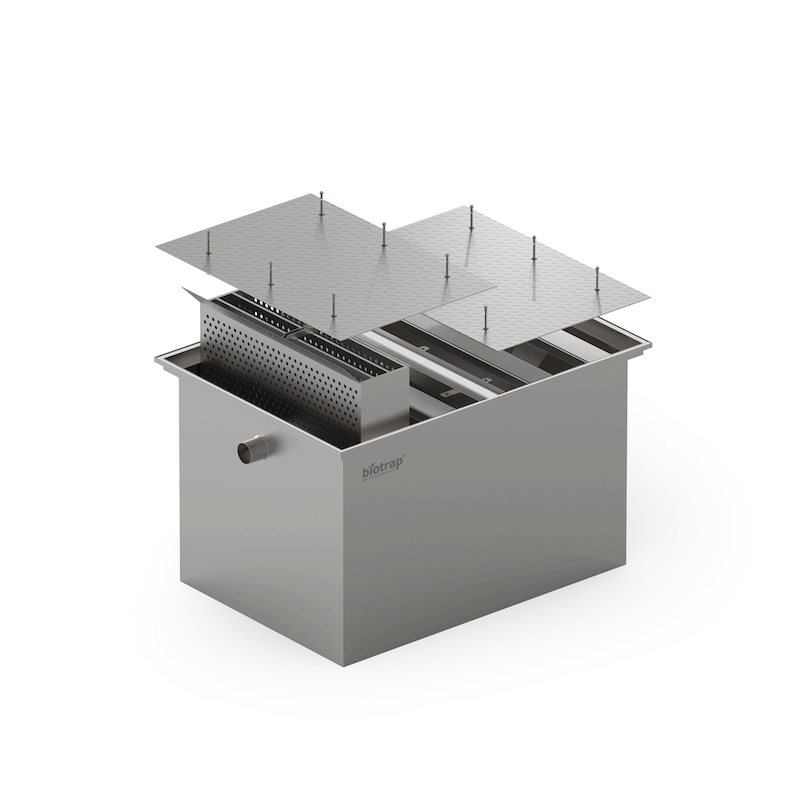

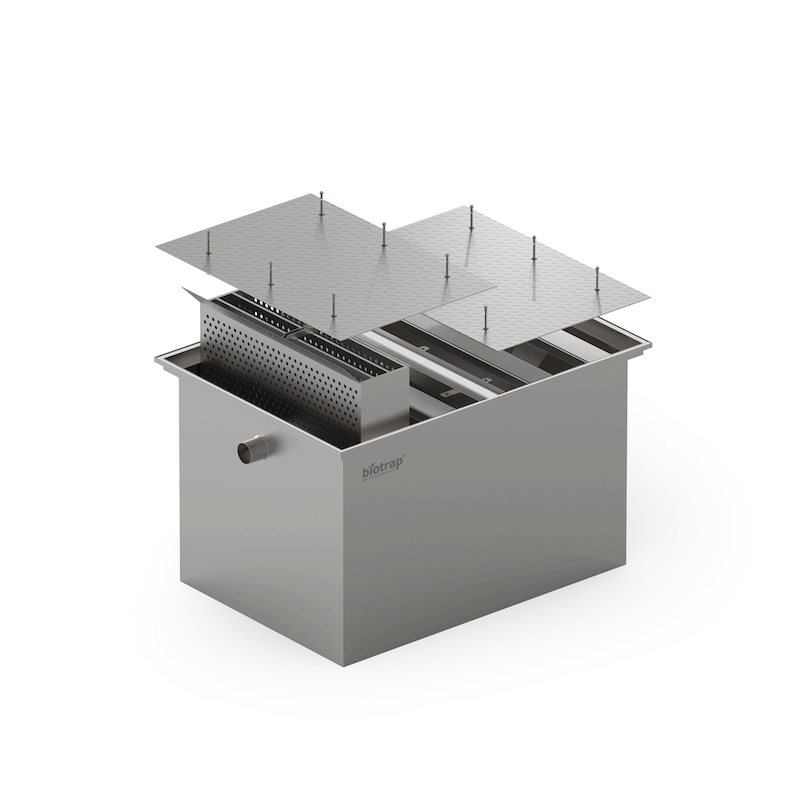

BIOTRAP-IBG

Indoor Below Ground

Materials: 304 stainless steel.

Inlet/Outlet Location: Optional.

Capacity: From 300 litres to any size.

Installation: 3-8 hours.

Lead-time: 35-40 working days.

Suitable for: Indoors. Both above and below ground.

BIOTRAP-OBG

Outdoor Below Ground

Materials: 304 stainless steel.

Inlet/Outlet Location: Optional.

Capacity: From 100 litres to any size.

Installation: 3-8 hours.

Lead-time: 35-40 working days.

Suitable for: Outdoors. Below ground only.

Covers: Load bearing covers for cars/vans/trucks.

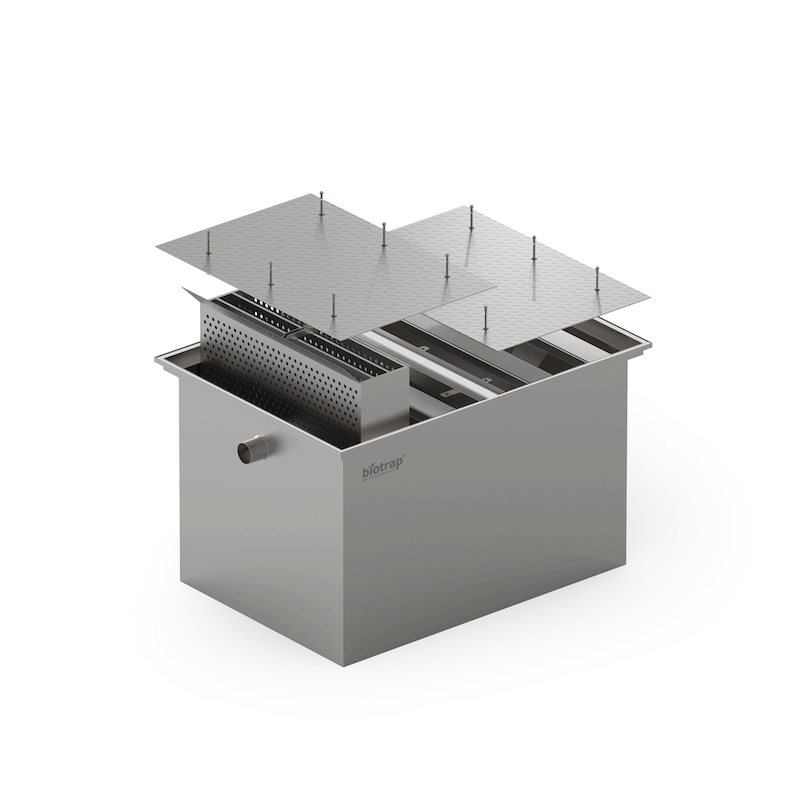

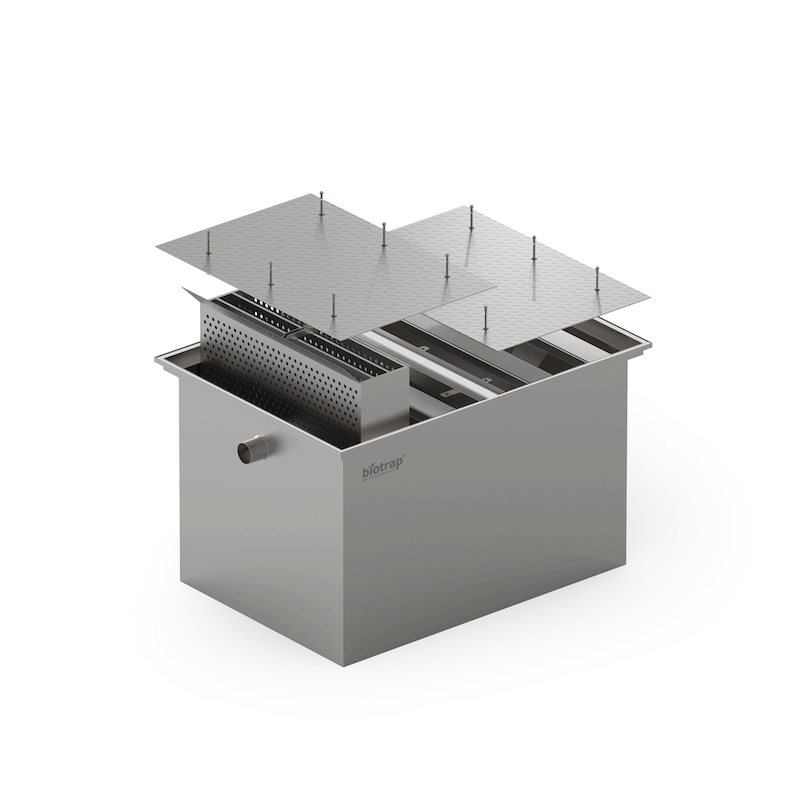

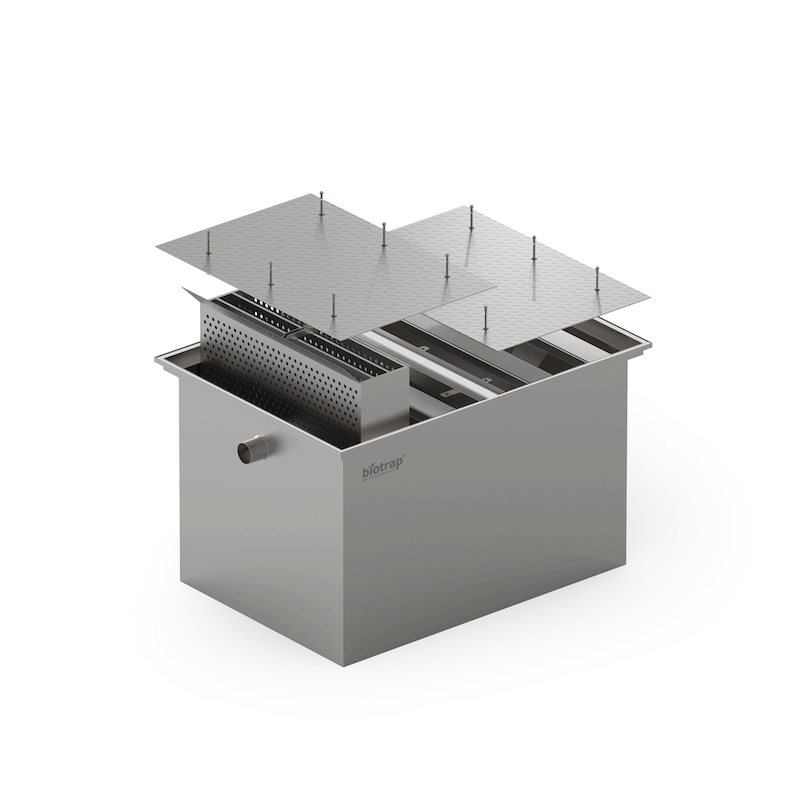

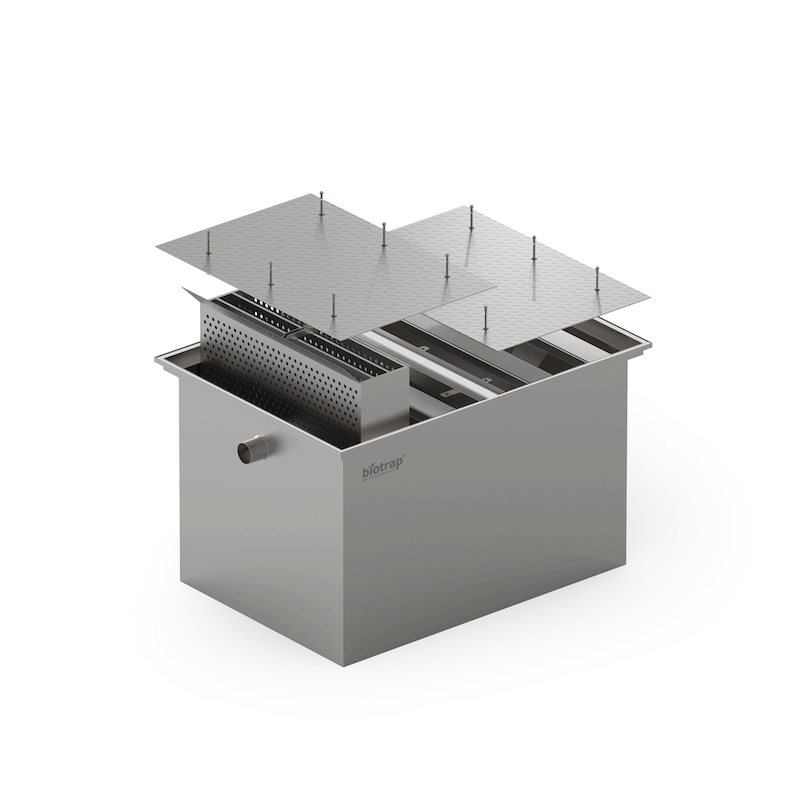

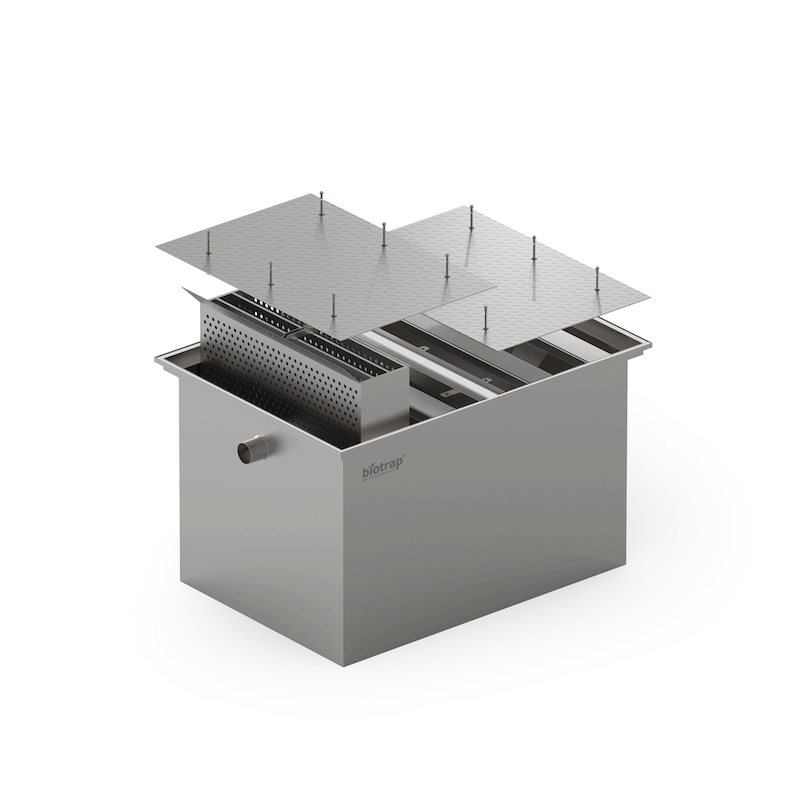

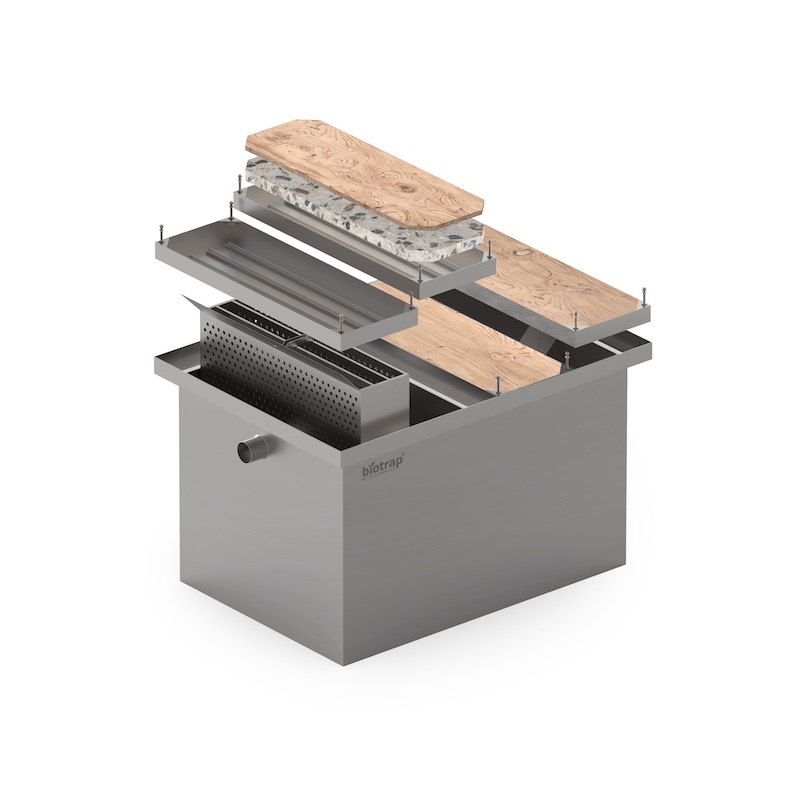

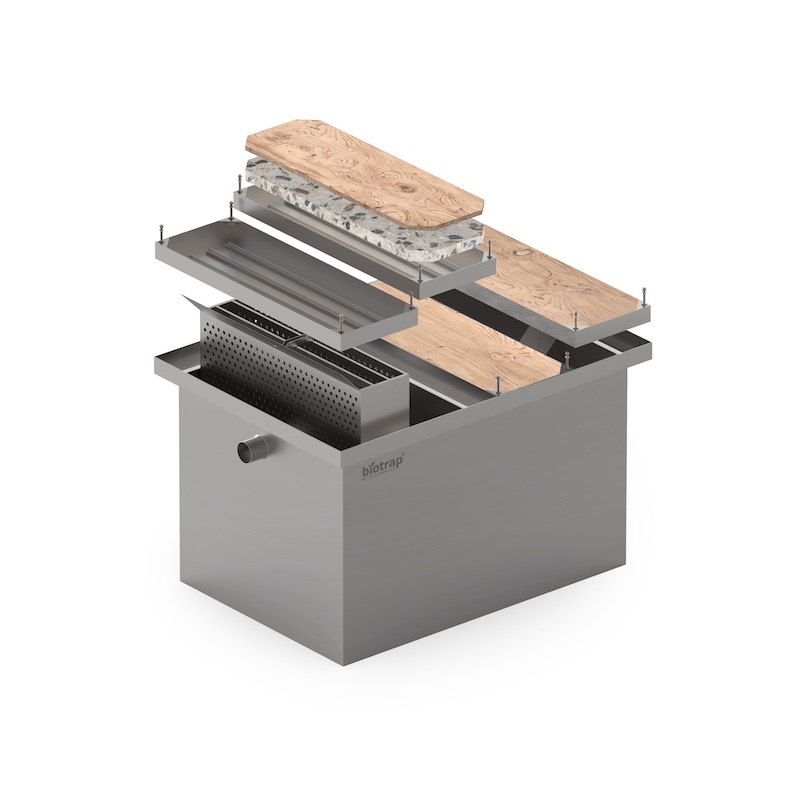

BIOTRAP-IBG(R)

Indoor Below Ground with Recessed Lid

Materials: 304 stainless steel.

Inlet/Outlet Location: Optional.

Capacity: From 300 litres to any size.

Installation: 3-8 hours.

Lead-time: 35-40 working days.

Suitable for: Indoors. Below ground only.

BIOTRAP-OBG(R)

Outdoor Below Ground with Recessed Lid

Materials: 304 stainless steel.

Inlet/Outlet Location: Optional.

Capacity: From 100 litres to any size.

Installation: 3-8 hours.

Lead-time: 35-40 working days.

Suitable for: Outdoors. Below ground only.

The BIOTRAP-AG lids are made from 304 grade stainless steel and are secured to the unit with several drop-down threaded knobs. No tools are required for opening and closing the lids.

The compression seals on the BIOTRAP-AG ensure a 100% airtight seal so it is perfectly suited for indoor (above ground) locations such as kitchens, store rooms, corridors etc.

The BIOTRAP-AG can be installed below the sewer line e.g. basements, carparks, cellars etc. A secondary holding tank is installed on the outlet side of the greasetrap where grey water is collected and pumped up to the main sewer line at ground level. (see pages 26 & 27).

The BIOTRAP-AG is available in 13 standard sizes (see pages 14 & 15) or it can be made to measure with variable inlet and outlet locations to suit existing on-site pipework.

We design, manufacture, install, and maintain an extensive range of grease-trapping equipment to suit the needs of all food operators. From cafes and restaurants to large scale food-production plants, we will ensure your premises complies with all industry standards, allowing you to focus on your core business.

The Taylormade BIOTRAP.

This 60-second video explains why food operators need a grease trap. It illustrates how a BIOTRAP® works compared to traditional grease traps and details the benefits of a taylormade maintenance plan.

We are happy to provide you with contact details for food operators in your location that have replaced their mechanical and passive grease trap with a taylormade BIOTRAP®.

Which Grease Trap is Right for my Premises?

This 90-second video compares the associated costs of an electrical grease trap with a passive BIOTRAP®. It also explains why the system requires zero input from staff and how it always passes an Irish Water Inspection.

We are happy to provide you with contact details for food operators in your location that have replaced their mechanical and passive grease trap with a taylormade BIOTRAP®.

A Day in our Workshop.

This 2 minute video captures a typical day in our workshop. See how our bacterial dosing equipment is assembled using the finest quality materials and then installed in a commerical kitchen.

We are happy to provide you with contact details for food operators in your location that have replaced their mechanical and passive grease trap with a taylormade BIOTRAP®.

BIOTRAP® Installation Timelapse.

This 20 second timelapse shows an undersink BIOTRAP being installed in a busy delicatesen. Note how the unit is 100% passive and requires zero maintenance from staff.