Right First Time

Correct Sizing. Assured Compliance.

I.S. EN 1825 parts 1 & 2 requires all grease traps to be correctly sized prior to installation. Sizing is based on the nature and quantity of the wastewater entering the grease trap while taking into account the maximum temperature and flow rate, the density of FOG’s (fats, oils & grease) to be separated and the influence of cleaning / rising agents. Maximum flow rates of wastewater can be determined by the measurment of (1), FOG producing catering equipment that is discharging into the grease trap or (2), the number of meals being served per day and hours of operation.

Selection & Installation Recommendations

- Determine the correct size by using the free sizing calculator below.

- The unit will need to be regularly emptied and cleaned so try to locate the trap within easy reach of a large service vehicle. Ensure there is sufficient head room to remove the access lids.

- If the trap is an underground model provide load-bearing requirements e.g. pedestrian, cars, HGV’s.

- Ensure a level 150mm concrete base.

- The unit must be vented to the outside of the building.

- Sewage systems, waste dispoal units, macerators, vegetable preparation areas and sluice sinks should not be connected to the grease trap.

- Allowance should be made for the installation of a automated bacterial dosing unit. The daily treatment should carry a DCC or Irish Water permit number.

Free Site Survey

Call now to book a free survey of your site. Our engineers can assist you with sizing, positioning, design, loading, etc.

Bespoke Riser

If the existing sewer line is situated more than 350mm below ground level, a riser will be required. This ensures the volume of the grease trap is not compromised.

Irish Water Application & Approval

Installing a grease trap without Local Authority consent could result in heavy fines and costly remediation works. Prior to fabrication, we will correctly size your grease trap and make an application to Irish Water on behalf of your client. This is a free service.

Size Scale

An undersized grease trap will not separate grease correctly as hot water from appliances will simply wash liquified FOG’s through the unit where it will later cool and solidfy in pipes and drains. Sizing a grease trap correctly requires a skilful assessment of the food service establishment. Critical information such as water temperatures, flow rates, meals served per day, etc. play a significant part in determining the volume of the unit. Investing in a non-compliant or off-the-shelf grease trap can prove costly and disruptive as Irish Water Inspectors can insist on it being replaced.

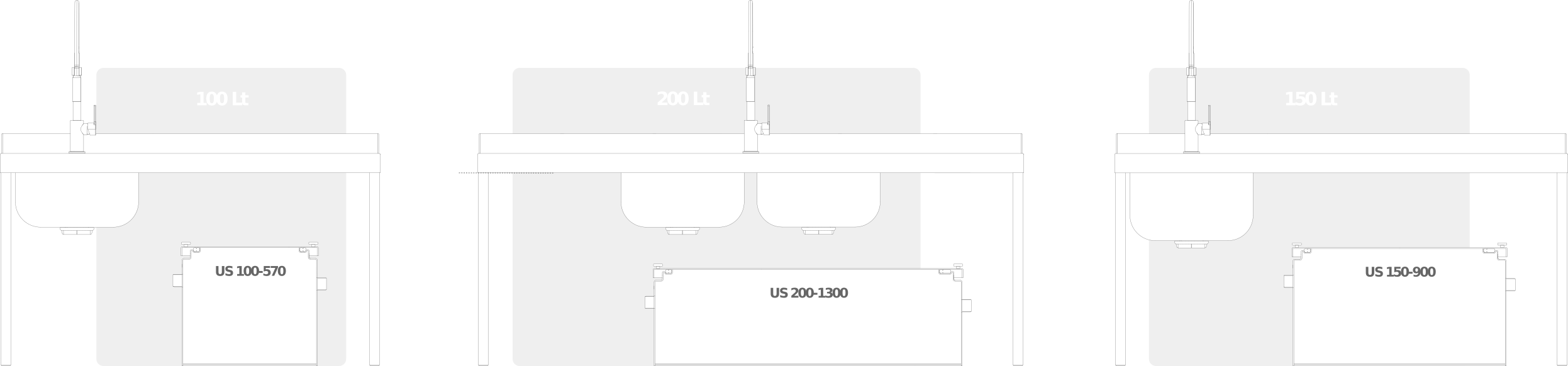

THE UNDER SINK RANGE

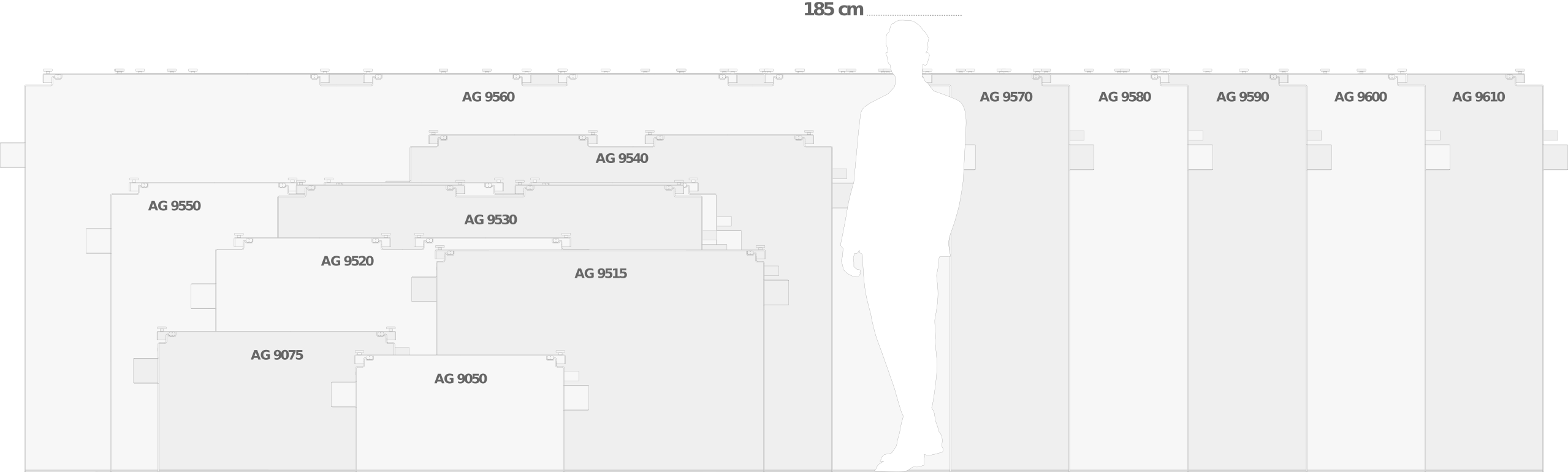

THE ABOVE GROUND RANGE

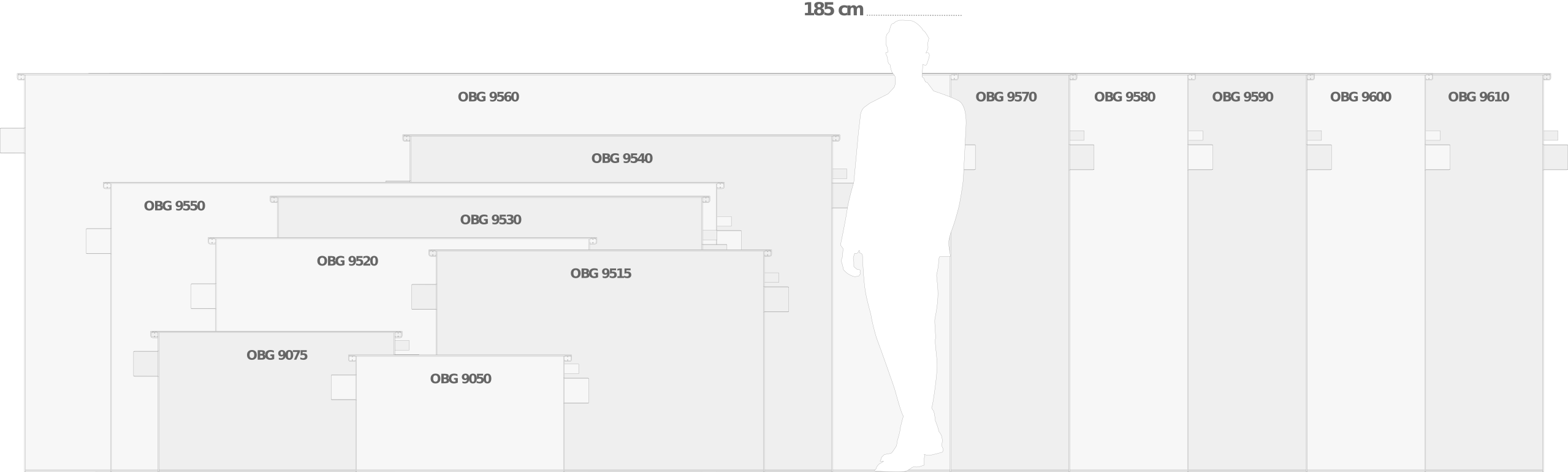

THE INDOOR & OUTDOOR BELOW GROUND RANGE

| Business Name (Optional) | Business Type | Water Temperature | Use of Rinsing Agents | Indoor or Outdoor | Above or Below | Meals per Day | Average Hours of Operation |

|---|---|---|---|---|---|---|---|

|

|

|

Business Type

Water Temperature

Use of Rinsing Agents

Indoor or Outdoor

Above or Below

Meals per Day

Average Hours of Operation

| Qs - Maximum Water Flow Rate | ft - Factor of Temperature | fr - Factor of Rinsing Agents |

|---|---|---|

| Qs - Maximum Water Flow Rate | |

|---|---|

| ft - Factor of Temperature | |

| fr - Factor of Rinsing Agents |

| NS - Nominal Size | Product Name | Dimensions |

|---|---|---|

| NS - Nominal Size | |

|---|---|

| Product Name | |

| Dimensions |

| Business Name (Optional) | Business Type | Water Temperature | Use of Rinsing Agents | Indoors or Outdoors | Above or Below Ground |

|---|---|---|---|---|---|

|

|

|

| Quantity | Type of Kitchen Equipment | Quantity | Type of Kitchen Equipment |

|---|---|---|---|

| Combi-oven | Dishwashers | ||

| Boiling Pan: 25mm Outlets | Boiling Pan: 50mm Outlets | ||

| Tilting Boiling Pan: 70mm Outlets | Tilting Boiling Pan: 100mm Outlets | ||

| Non-Siphonic Rinse Sinks: 40mm Outlets | Non-Siphonic Rinse Sinks: 50mm Outlets | ||

| Siphonic Rinse Sinks: 40mm Outlets* | Siphonic Rinse Sinks: 50mm Outlets* | ||

| Tilting Roasting Tins | Fixed Roasting Tins | ||

| High Pressure Cleaner/Steamers | Scrapers | ||

| Vegetable Peeling/Rumbler Units | Wok Stations |

| Qs - Maximum Water Flow Rate | ft - Factor of Temperature | fr - Factor of Rinsing Agents |

|---|---|---|

Business Type

Water Temperature

Use of Rinsing Agents

Indoor or Outdoor

Above or Below

| Type of Kitchen Equipment | Quantity |

|---|---|

| Dishwashers | |

| Boiling Pan: 50mm Outlets | |

| Tilting Boiling Pan: 100mm Outlets | |

| Non-Siphonic Rinse Sinks: 50mm Outlets | |

| Siphonic Rinse Sinks: 50mm Outlets* | |

| Fixed Roasting Tins | |

| Scrapers | |

| Wok Stations | |

| Combi-oven | |

| Boiling Pan: 25mm Outlets | |

| Tilting Boiling Pan: 70mm Outlets | |

| Non-Siphonic Rinse Sinks: 40mm Outlets | |

| Siphonic Rinse Sinks: 40mm Outlets* | |

| Tilting Roasting Tins | |

| High Pressure Cleaner/Steamers | |

| Vegetable Peeling/Rumbler Units |

| Qs - Maximum Water Flow Rate | |

|---|---|

| ft - Factor of Temperature | |

| fr - Factor of Rinsing Agents |

| NS - Nominal Size | |

|---|---|

| Product Name | |

| Dimensions |

Integrated Lids

All our indoor and outdoor below ground models are supplied with integrated pedestrian lids as standard. This means that the removable lids, when secured, are connected directly to the greasetrap (unlike the independent lid option). Load bearing-lids can accommodate pedestrian traffic, cars, or HGV’s.

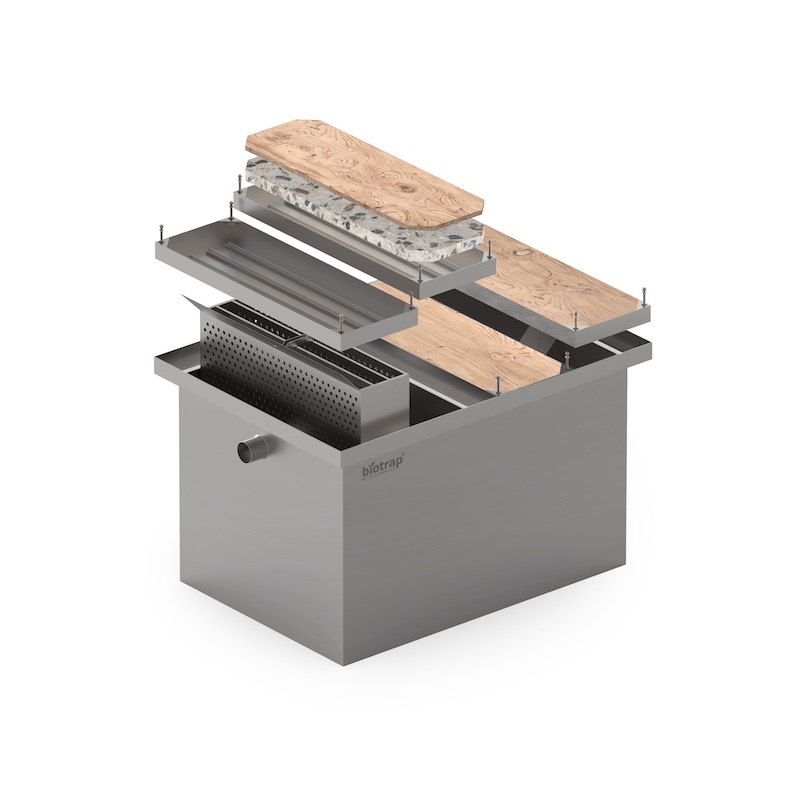

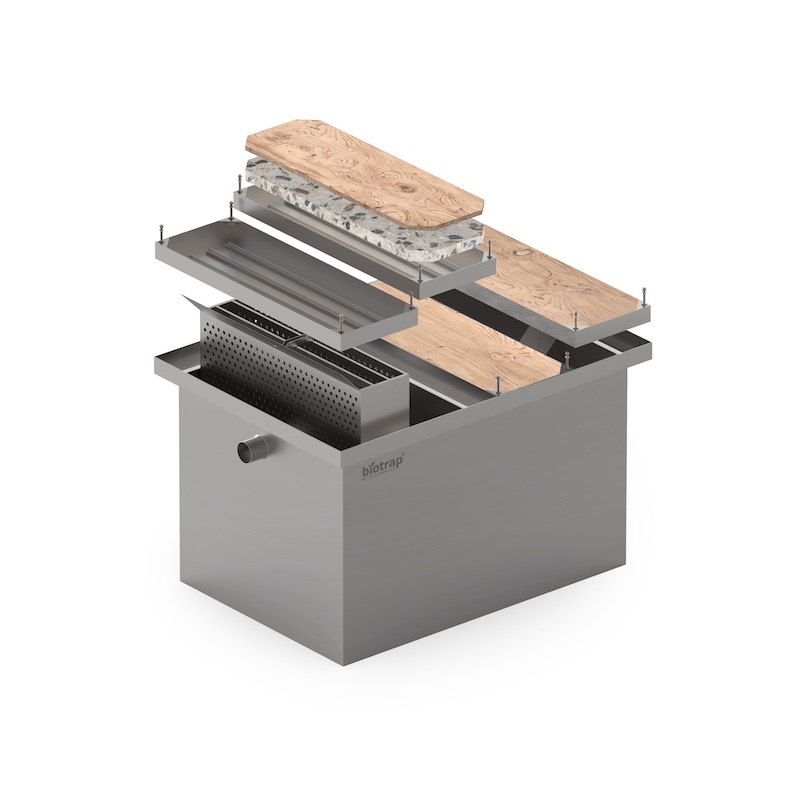

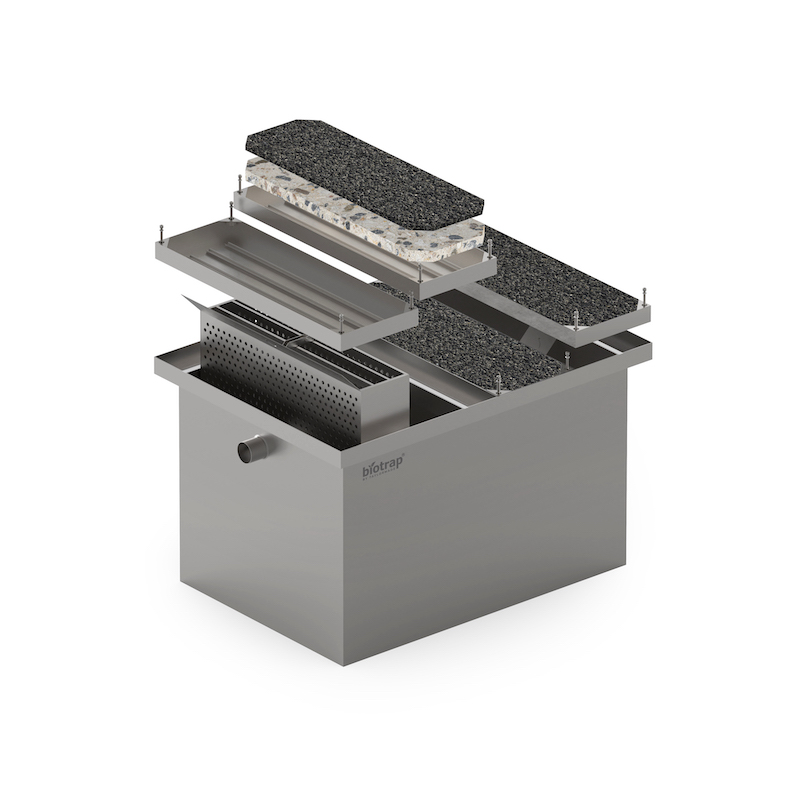

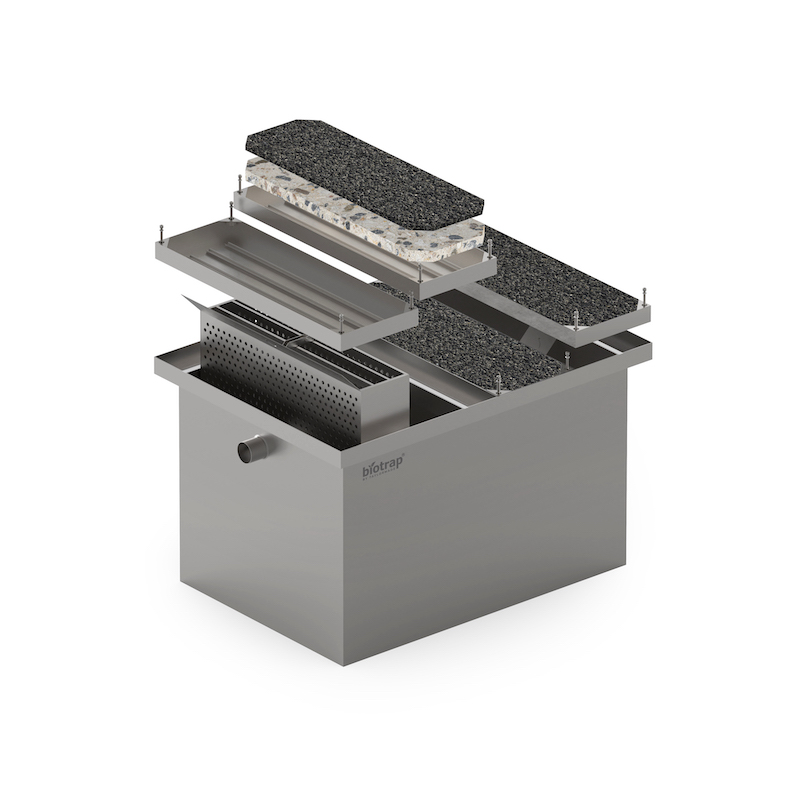

Recessed Lids

Recessed lids are the ideal way to minimise the visual impact of a greasetrap in an area of high foot traffic or where a continuous tarmac, concrete, cobble-lock, tile, or timber effect needs to be achieved. Each lid is secured to the base unit with x4 threaded bolts which are located in each corner. The compression seals ensure a 100% airtight seal, so they are perfectly suited for any indoor or outdoor (underground) location.

Integrated Lids

All our indoor and outdoor below ground models are supplied with integrated pedestrian lids as standard. This means that the removable lids, when secured, are connected directly to the greasetrap (unlike the independent lid option). Load bearing-lids can accommodate pedestrian traffic, cars, or HGV’s.

Recessed Lids

Recessed lids are the ideal way to minimise the visual impact of a greasetrap in an area of high foot traffic or where a continuous tarmac, concrete, cobble-lock, tile, or timber effect needs to be achieved. Each lid is secured to the base unit with x4 threaded bolts which are located in each corner. The compression seals ensure a 100% airtight seal, so they are perfectly suited for any indoor or outdoor (underground) location.

Integrated Lids

All our indoor and outdoor below ground models are supplied with integrated pedestrian lids as standard. This means that the removable lids, when secured, are connected directly to the greasetrap (unlike the independent lid option). Load bearing-lids can accommodate pedestrian traffic, cars, or HGV’s.

Independent Lids

All our indoor and outdoor below ground models can be supplied with independant lids. This allows the greasetrap to be installed below finish floor level i.e. where the existing pipework is located deep in the ground. Independent load bearing lids can accommodate pedestrian traffic, cars, or HGV’s.

Integrated Lids

All our indoor and outdoor below ground models are supplied with integrated pedestrian lids as standard. This means that the removable lids, when secured, are connected directly to the greasetrap (unlike the independent lid option). Load bearing-lids can accommodate pedestrian traffic, cars, or HGV’s.

Independent Lids

All our indoor and outdoor below ground models can be supplied with independant lids. This allows the greasetrap to be installed below finish floor level i.e. where the existing pipework is located deep in the ground. Independent load bearing lids can accommodate pedestrian traffic, cars, or HGV’s.

Integrated Lids

All our indoor and outdoor below ground models are supplied with integrated pedestrian lids as standard. This means that the removable lids, when secured, are connected directly to the greasetrap (unlike the independent lid option). Load bearing-lids can accommodate pedestrian traffic, cars, or HGV’s.

Independent Lids

All our indoor and outdoor below ground models can be supplied with independant lids. This allows the greasetrap to be installed below finish floor level i.e. where the existing pipework is located deep in the ground. Independent load bearing lids can accommodate pedestrian traffic, cars, or HGV’s.

Integrated Lids

All our indoor and outdoor below ground models are supplied with integrated pedestrian lids as standard. This means that the removable lids, when secured, are connected directly to the greasetrap (unlike the independent lid option). Load bearing-lids can accommodate pedestrian traffic, cars, or HGV’s.

Independent Lids

All our indoor and outdoor below ground models can be supplied with independant lids. This allows the greasetrap to be installed below finish floor level i.e. where the existing pipework is located deep in the ground. Independent load bearing lids can accommodate pedestrian traffic, cars, or HGV’s.

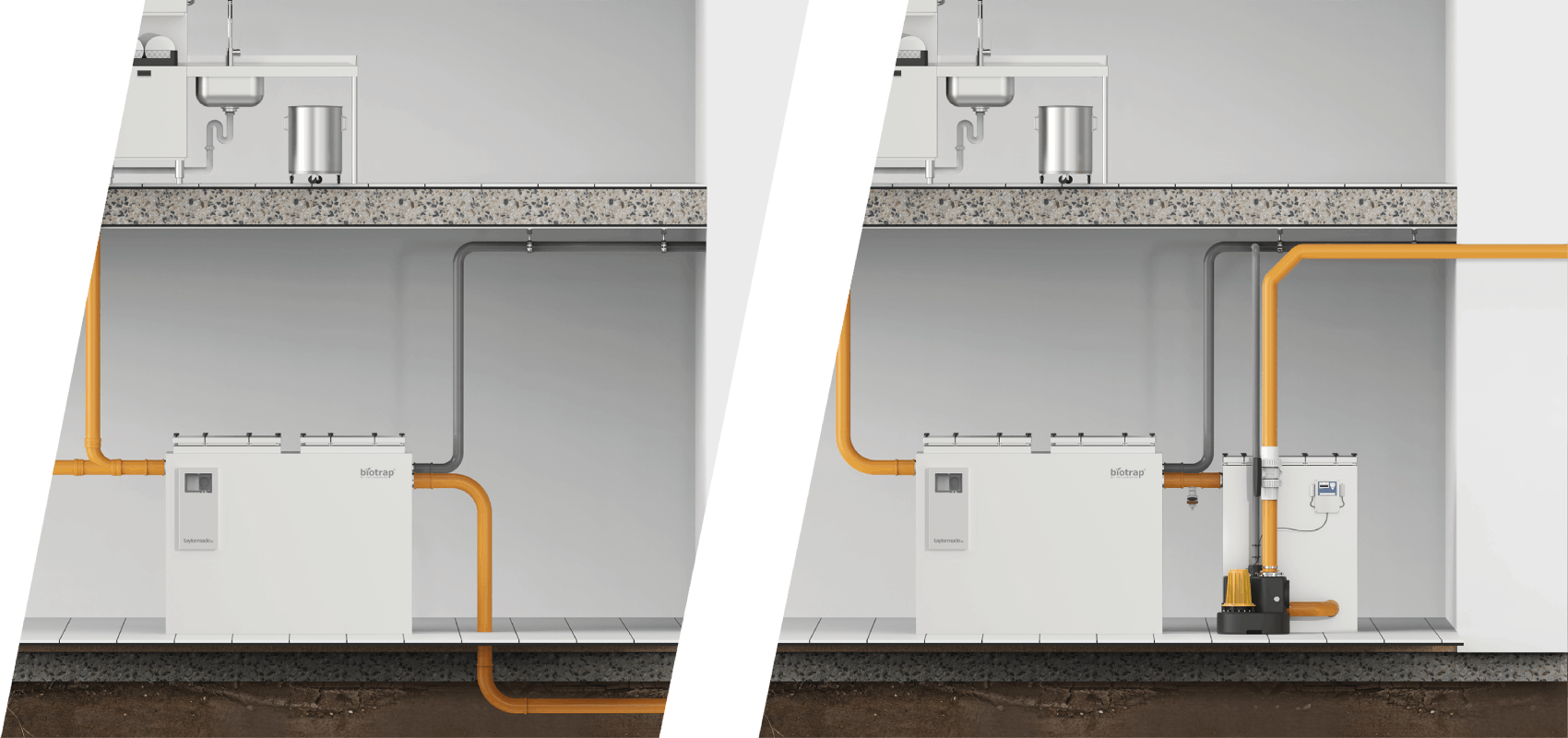

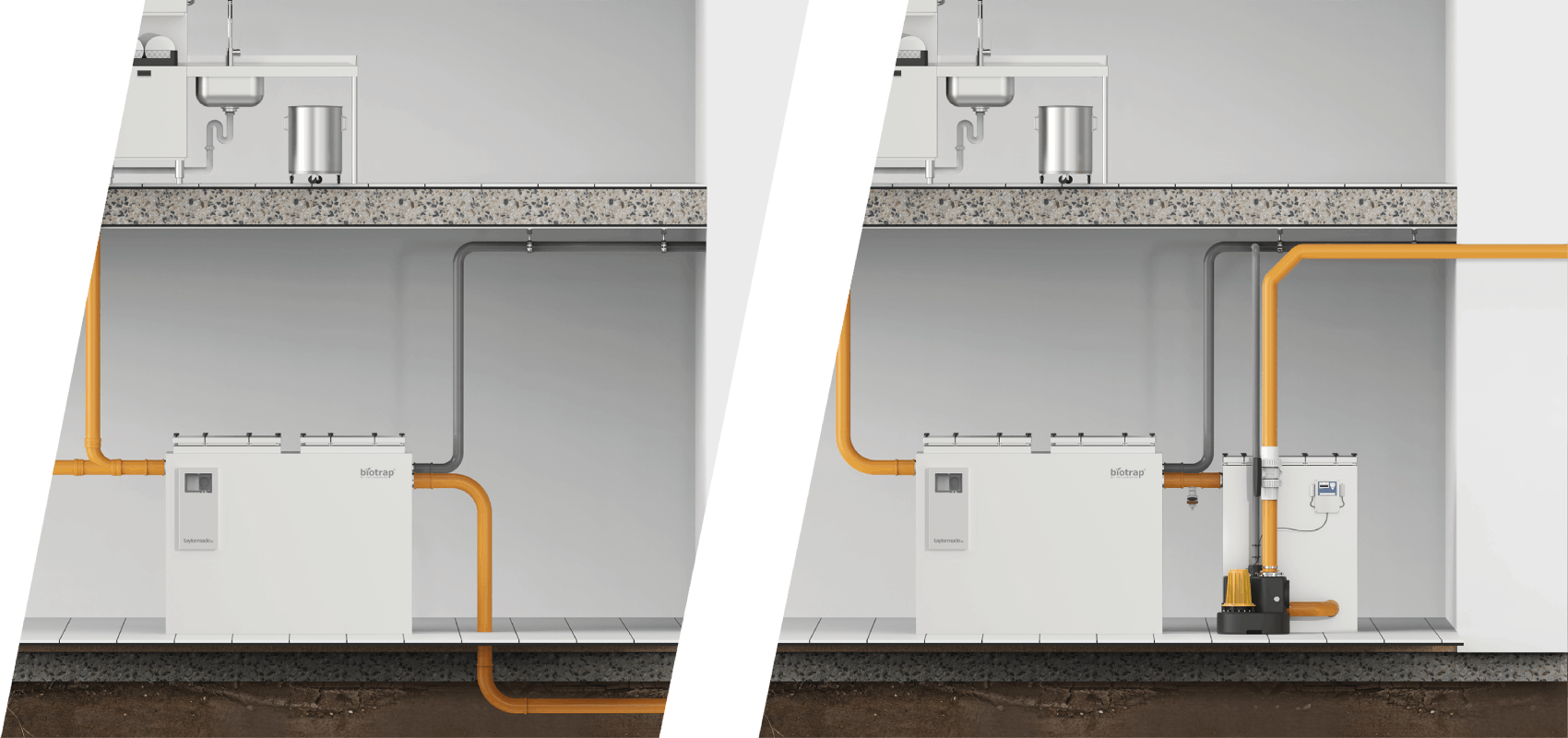

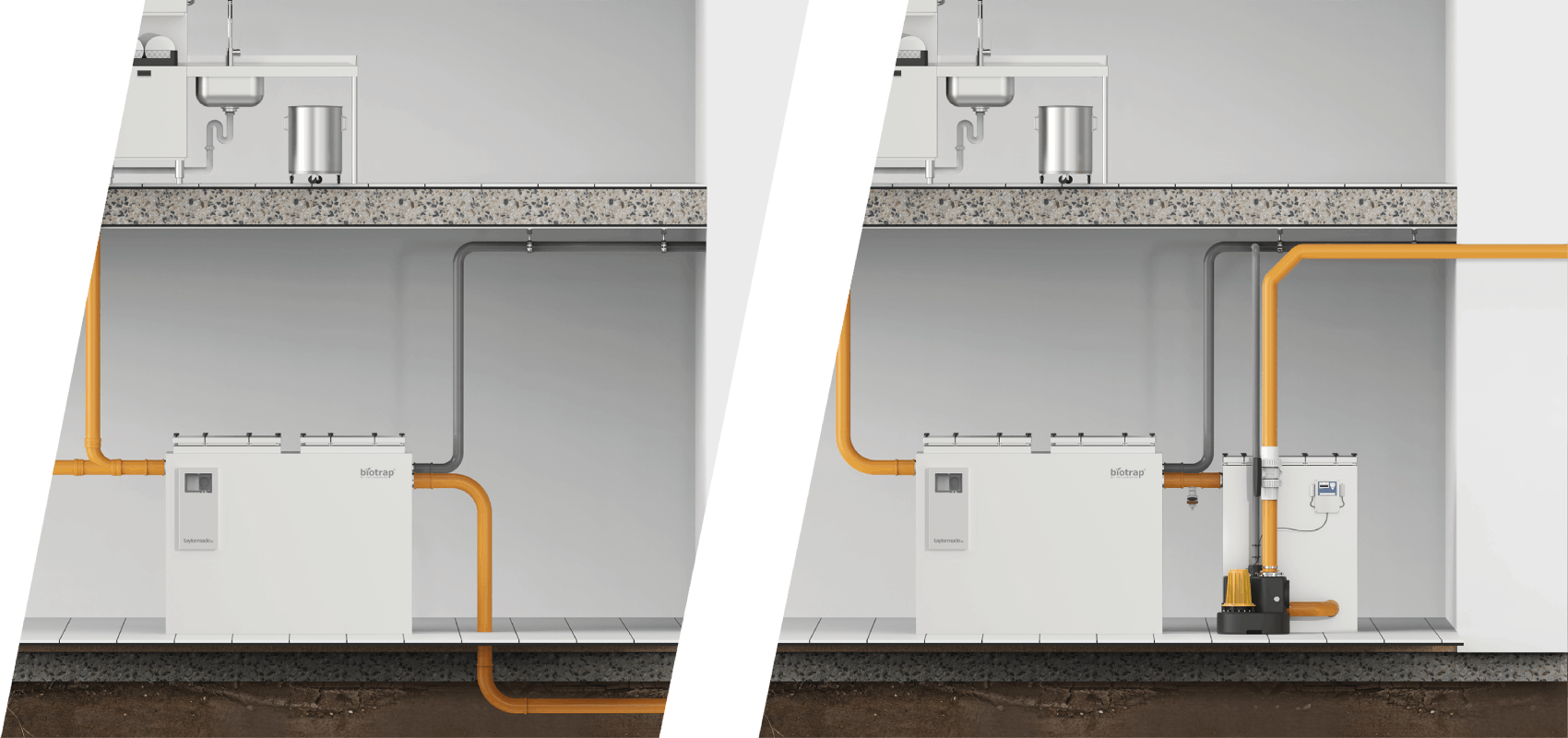

Gravity-Fed BIOTRAP®

The BIOTRAP-AG range is specifically designed for above ground applications where grey water leaving the greasetrap is gravity fed into a main sewer line. Constructed from 304 stainless steel throughout, the BIOTRAP-AG is available in 13 standard sizes with variable inlet and outlet locations to suit existing on-site pipework.

BIOTRAP® with Lifting Pump

The BIOTRAP-AG range with grey water holding tank and lifting pump is designed for basement applications where grey water leaving the greasetrap needs to be pumped up to the main sewer line at ground level. The grey water holding tank is typically one third the volume of the greasetrap.

Gravity-Fed BIOTRAP®

The BIOTRAP-AG range is specifically designed for above ground applications where grey water leaving the greasetrap is gravity fed into a main sewer line. Constructed from 304 stainless steel throughout, the BIOTRAP-AG is available in 13 standard sizes with variable inlet and outlet locations to suit existing on-site pipework.

BIOTRAP® with Lifting Pump

The BIOTRAP-AG range with grey water holding tank and lifting pump is designed for basement applications where grey water leaving the greasetrap needs to be pumped up to the main sewer line at ground level. The grey water holding tank is typically one third the volume of the greasetrap.

Car Park

Unique Features

• Removable lids for thorough cleaning

• Removable baffles

• 100% airtight design

• Variable inlet & outlet locations

• Can be made in several sections – welded on site

• Passive unit with no running costs

• Optional SLA (Service Level Agreement)

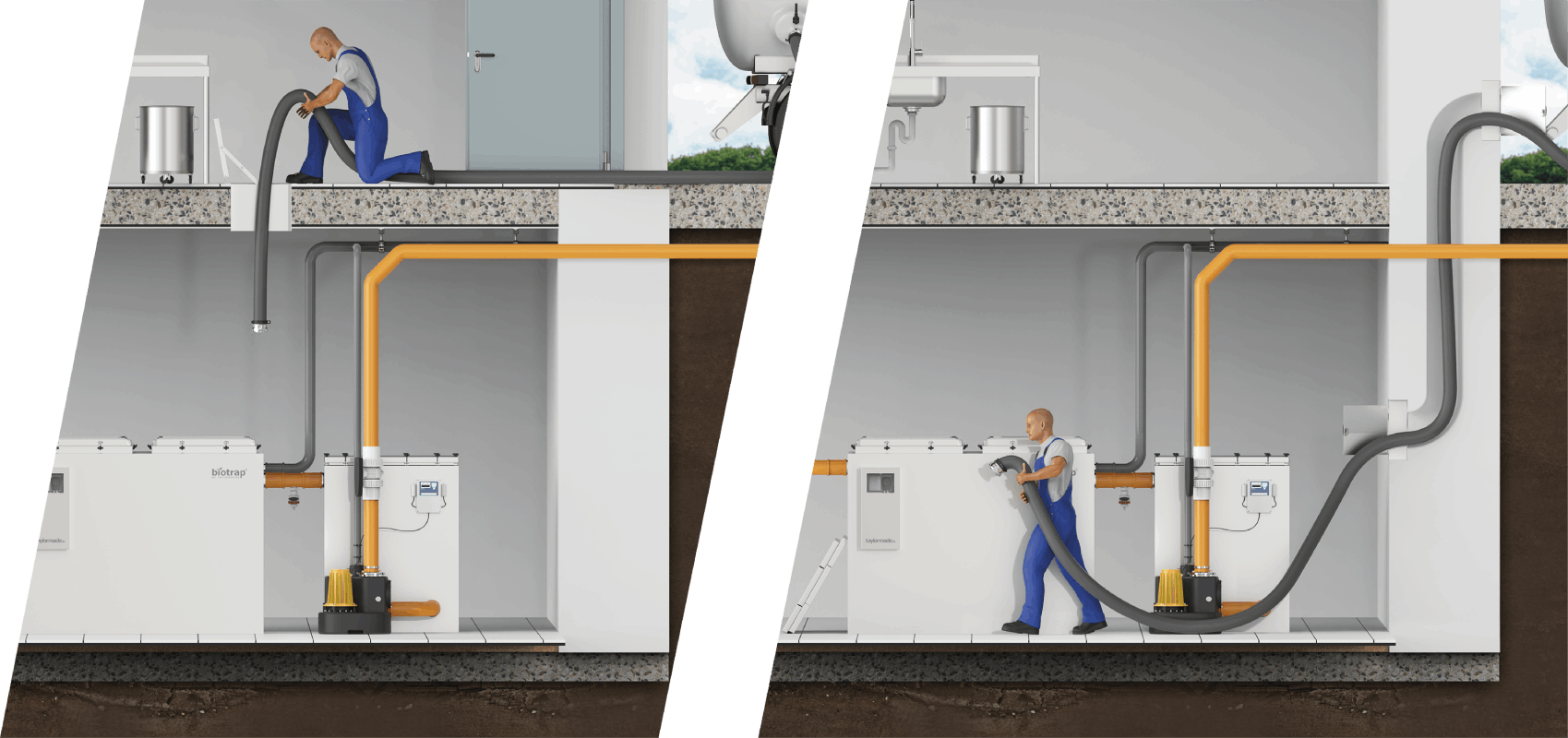

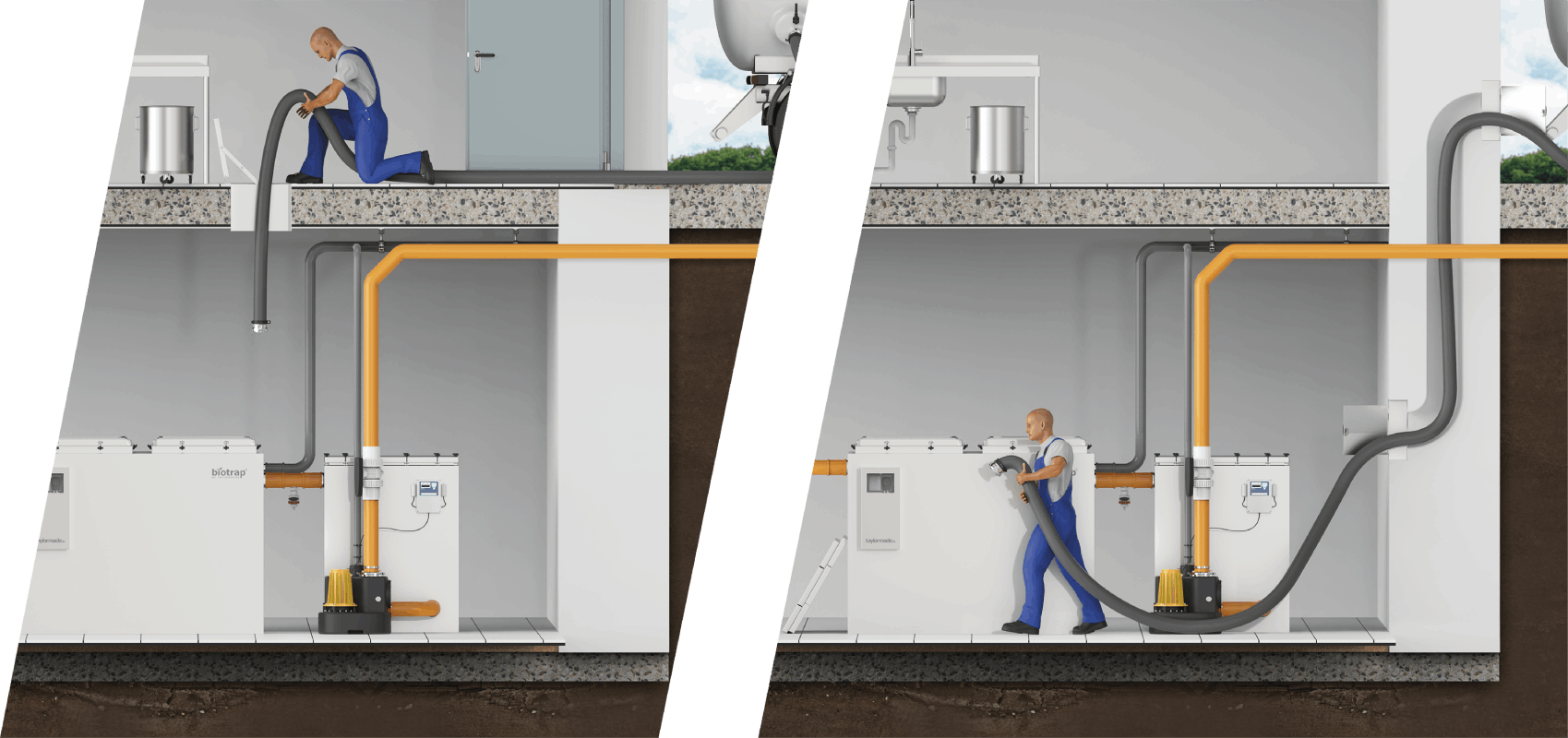

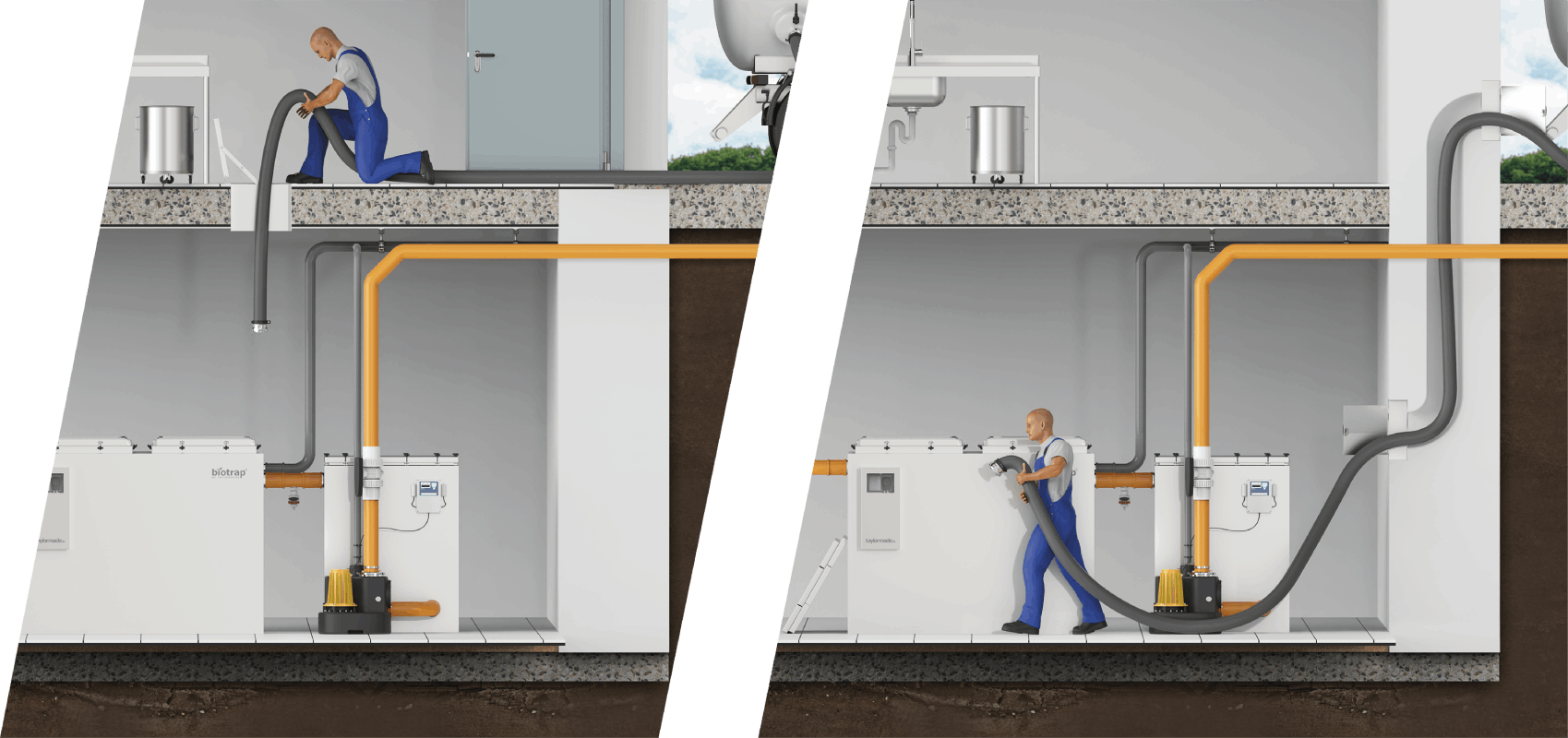

Option 1

Provide easy access for emptying and washdown by installing our custom-built Service Access Hatch in the floor above the greasetrap location. The vacuum pipe-run from truck to greasetrap is typically 80 metres.

Option 2

Basement level greasetraps are easy to maintain when a Service Access Chute is installed within the buildings structure. The lockable doors are vandal proof and fabricated from 304 stainless steel.

Option 1

Provide easy access for emptying and washdown by installing our custom-built Service Access Hatch in the floor above the greasetrap location. The vacuum pipe-run from truck to greasetrap is typically 80 metres.

Option 2

Basement level greasetraps are easy to maintain when a Service Access Chute is installed within the buildings structure. The lockable doors are vandal proof and fabricated from 304 stainless steel.

The Below Ground Range

Recessed Lids to Accept Any Floor Type.

Recessed lids are the ideal way to minimise the visual impact of a greasetrap in an area of high foot traffic or where a continuous tarmac, concrete, cobble-lock, tile, or timber effect needs to be achieved. Each lid is secured to the base unit with x4 threaded bolts which are located in each corner.

Our recessed lid model will accommodate pedestrian traffic or light goods trolleys and pallet trucks. HGV and car lids are also available. The lid design ensures the unit can be thoroughly cleaned and washed down in compliance with I.S. EN 1825 parts 1 & 2.

The recessed model can be supplied with independent or integrated lids. The compression seals ensure a 100% airtight seal so they are perfectly suited for any indoor or outdoor (underground) location. As with all our BIOTRAPS, the recessed model comes with variable inlet/outlet locations.